Acoustic Foams

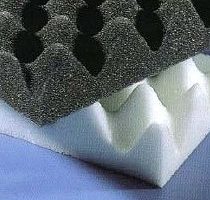

Composite Foam

Acousti-Composite is a noise control material specifically designed to achieve maximum attenuation over a broad frequency range. Acousti-Composite combines dense, limp, flexible, non-lead loaded barriers with Acousti-Foams providing a total noise control system. Unlike other composites available, these multilayer systems are manufactured without costly adhesives, thus eliminating the potential for failure between layers.

PDF Spec Sheets: Composite Foam

Designed by acoustical engineers, Acousti-Composite has been optimized to economically provide:

- High Transmission Loss - the barrier's ability to impede airborne noise.

- High Noise Reduction Coefficients - the foam's ability to absorb airborne sound energy with minimum reflections.

- Damping - the composite's ability to attenuate structure-borne vibration on metals and plastics. Thereby reducing reradiated noise and material fatigue.

The diversity of constructions makes possible engineered solutions for most OEM and in-plant applications. Acousti-Composite is available with single and double layer septums, various barrier weights, foam thicknesses and a variety of surface treatments. Composite is available in rolls, sheets, die cut or fabricated to customer specifications or can be easily field cut with a knife or scissors. These composites can be adhered to the substrate with factory supplied, economical, SBR pressure sensitive adhesive or an acrylic based pressure sensitive adhesive for temperatures up to 250°F. It is recommended that a contact adhesive or mechanical fasteners be used for these heavily loaded composites in overhead applications.

Melamine Foam

Melamine is a lightweight, high temperature resistant, open cell foam manufactured from melamine resin. It combines excellent thermal properties with superior sound absorption capabilities to create a versatile fiber free product which can be applied in situations which may prohibit the use of urethane foams or fiberglass insulations. This fire retardant foam meets the flame spread, smoke density and fuel contribution requirements necessary to comply with Class-l building code regulations. The high performance thermal and acoustical characteristics of this flexible, low density foam make it an ideal product for in-plant and FDA approved applications. In addition to being the solution to aircraft and architectural noise problems, Acousti-Foam Melamine Foam is the material to use in OEM products requiring a combination of thermal and acoustical insulation capabilities. Optional facings can be applied for more durability and chemical resistance as well as pressure sensitive adhesive for ease of installation. Standard Sizes - Sheets: 24: x 48″, 48″ x 48″, 48″ x 96″ Standard Thickness: 1/4″ to 18″

PDF Spec Sheets: Melamine Foam

Product Data

- Color: White

- Density: .7 Ib/ft3 ASTM D3574-86 test A

- Tear Strength: .5 ppi per ASTM D3574-86 test F

- Tensile Strength: 18 psi per ASTM D3574-86 test E

- Elongation: 15% per ASTM D3574-86 test E

- Flammability: UL 94VO, UL-94 HF-1, UL 94-5,and FAR 25.853(a) ASTM E84

- Flame: 2.5; Smoke: 16.9 ASTM E162 Pass 662 Pass Boeing ATS 1000.001 Pass

- Thermal Conductivity: BTU/hr., Ft.2, °F/in.; .25 per ASTM C 177

- Temperature: -45°F – 302°F Continuous; to 400°F Intermittent

Many applications require these products to be subjected to environments such as dirt, moisture, chemicals, and abrasion that could be hostile to an unprotected foam. IES-2000 has developed various surface treatments to protect the integrity of the foam from these elements. These facings will increase the absorption properties at certain frequencies as well as provide a cleanable, decorative and durable finish for a wide variety of applications.

Optional Facings Available

- Aluminized Polyester

- Reinforced Aluminized Polyester

- Urethane Films (matte or impervious)

- Tedlar® (trademark E.I. Dupont Co.)

- Perforated Vinyl

- Convoluted

- Embossed

- Customized Facings Available

Pressure Sensitive Adhesive

- Supported SBR (temps to 140°F)

- Supported Acrylic (temps to 250°)

- Unsupported Acrylic (temps to 250°)

Polyurethane Foam

Acousti-Foam acoustical foams are designed to provide maximum absorption of airborne sound with minimum thickness and weight. These flexible polyurethane open cell foam products are manufactured to optimize pore size, air flow resistance, and density. Sound energy, passing through the cell structure, is converted into minute quantities of low grade heat that is easily dissipated. Since the uniformity of the cells are carefully controlled the efficiency is constant and predictable from one installation to another. Many applications require these products to be subjected to environments such as dirt, moisture, chemicals, and abrasion that could be hostile to an unprotected foam. IES-2000, Inc. has developed various surface treatments to protect the integrity of the foam from these elements. These facings will increase the absorption properties at certain frequencies as well as provide a cleanable, decorative and durable finish for a wide variety of applications. Acousti-Foams can be purchased in rolls or sheets, and can be die cut, or fabricated to customer specifications. They are easily cut with a knife, saw or scissors. The addition of pressure sensitive adhesive provides a convenient method of fastening to most substrates.

PDF Spec Sheets: Polyurethane Foam

Optional Facings Available

- Aluminized Polyester

- Reinforced Aluminized Polyester

- Urethane Films (matte or impervious)

- Tedlar® (trademark E.I. Dupont Co.)

- Perforated Vinyl

- Convoluted

- Embossed

- Customized Facings Available

Pressure Sensitive Adhesive

- Supported SBR (temps to 140°F)

- Supported Acrylic (temps to 250°)

- Unsupported Acrylic (temps to 250°)

| Thickness | Frequency - ASTM C423-903 - Absorption Coefficient | ||||||

|---|---|---|---|---|---|---|---|

| 125125 | 250250 | 500500 | 1K1K | 2K2K | 4K4K | NRCNRC | |

| 1251/2" | 250.00 | 500.08 | 1K.16 | 2K.55 | 4K.98 | NRCFrequency - ASTM C423-903 - Absorption Coefficient .95 | .45 |

| 1253/4" | 250.01 | 500.11 | 1K.38 | 2K.92 | 4K.93 | NRCFrequency - ASTM C423-903 - Absorption Coefficient .86 | .60 |

| 1251" | 250.06 | 500.19 | 1K.74 | 2K1.00 | 4K.85 | NRCFrequency - ASTM C423-903 - Absorption Coefficient .97 | .70 |

| 1251-1/2" | 250.10 | 500.30 | 1K.77 | 2K1.04 | 4K .99 | NRCFrequency - ASTM C423-903 - Absorption Coefficient1.11 | .80 |